Barus energy can build high-performance melt blown Fabric production line. We can design and produce the entire equipment to meet your needs. If you want to launch new production line, we’ll help you.

Our PP melt blown fabric production line can produce high quality PP melt blown fabrics. The meltblown equipment runs stably, with high output and high efficiency. The melt-blown process uses high-speed hot air to draw a thin stream of polymer melt extruded from the die orifice, thereby forming ultra-fine fibers and condensing on the screen or roller, and relying on self-adhesion and become a non-woven fabric.

The process flow is: Polymer mixing -> Melt extrusion -> Filter -> Melt pump -> Die -> Electret treatment -> Winding system

Technical Specification

| Model |

Production Width (mm) |

GSM Range (g/sq.m) |

Capacity (T/day) |

Max speed (m/min) |

| YL-800 | 800 | 10-200 | 0.72 | 80 |

| YL-1600 | 1600 | 10-200 | 1.5 | 80 |

| YL-2400 | 2400 | 10-200 | 2.4 | 80 |

EQUIPMENT LIST OF MELT BLOWN FABRIC PRODUCTION LINE

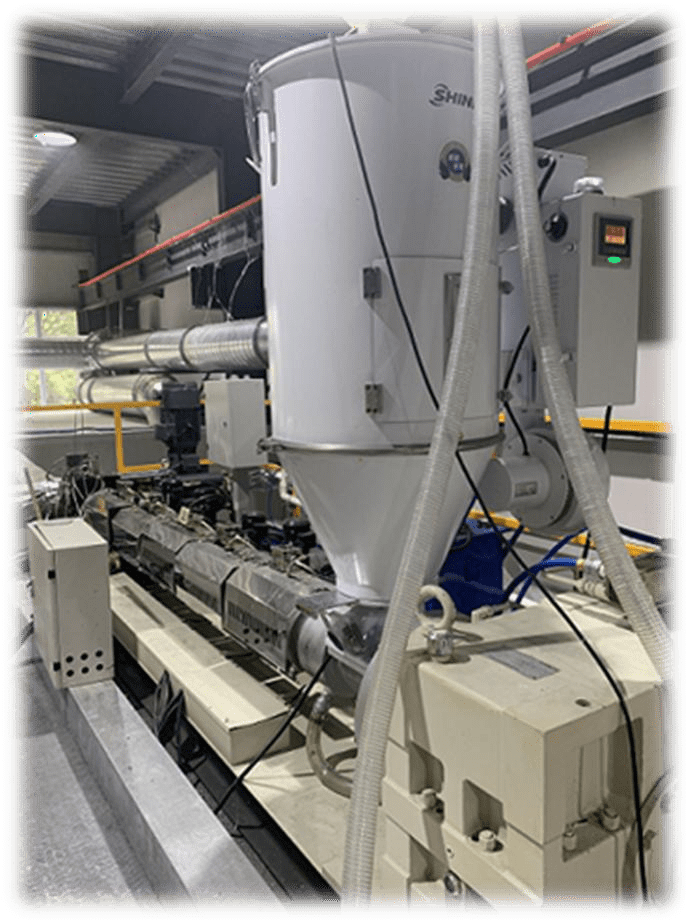

- Resin Dryer/Resin Transfer Machine

- Screw Extruder

- Filter and melt Pump Unit

- Heating System for Hot Air

- Melt-blown Box (T-Die, Distribution, Spinneret)

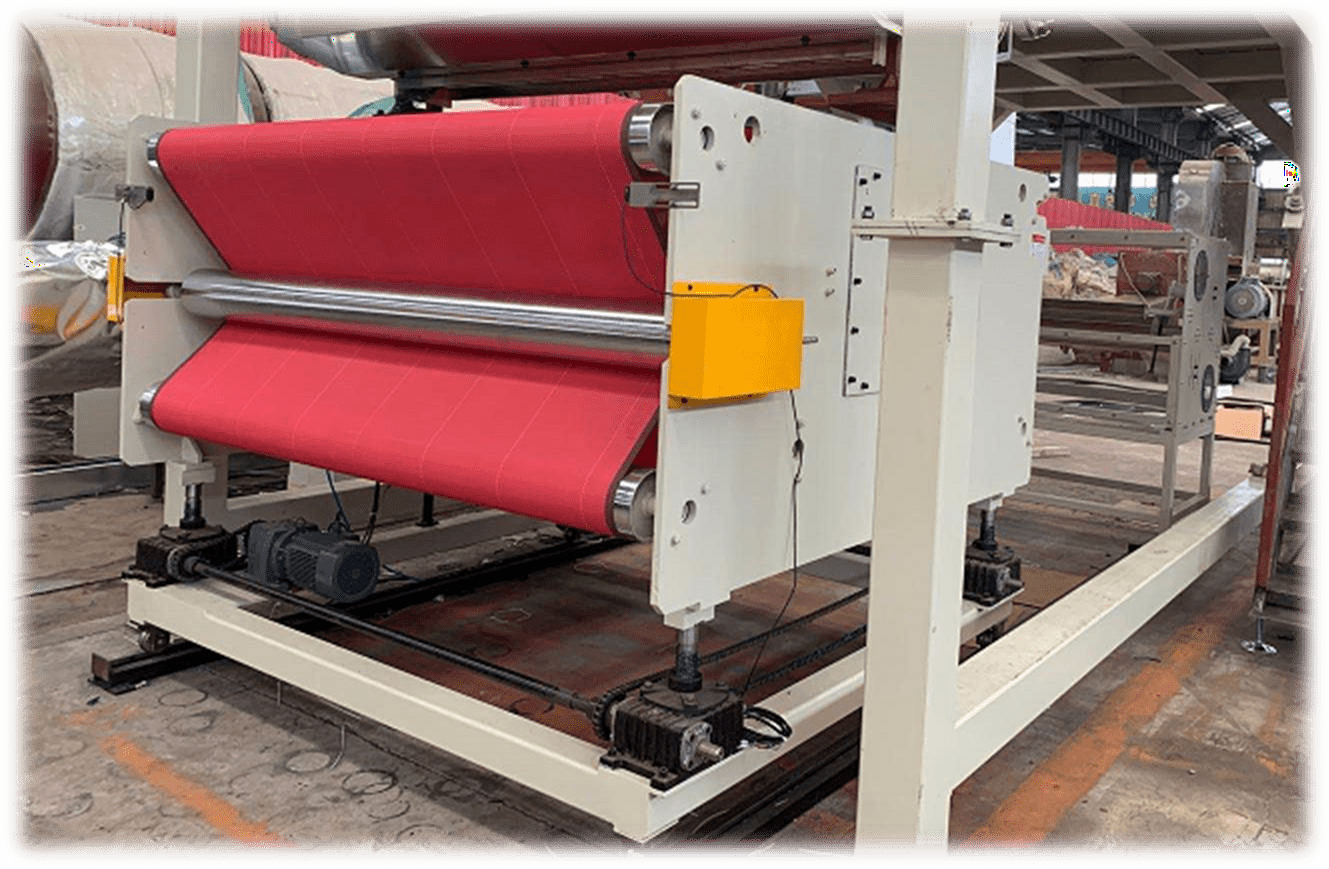

- Collection Device (Conveyor or Drum)

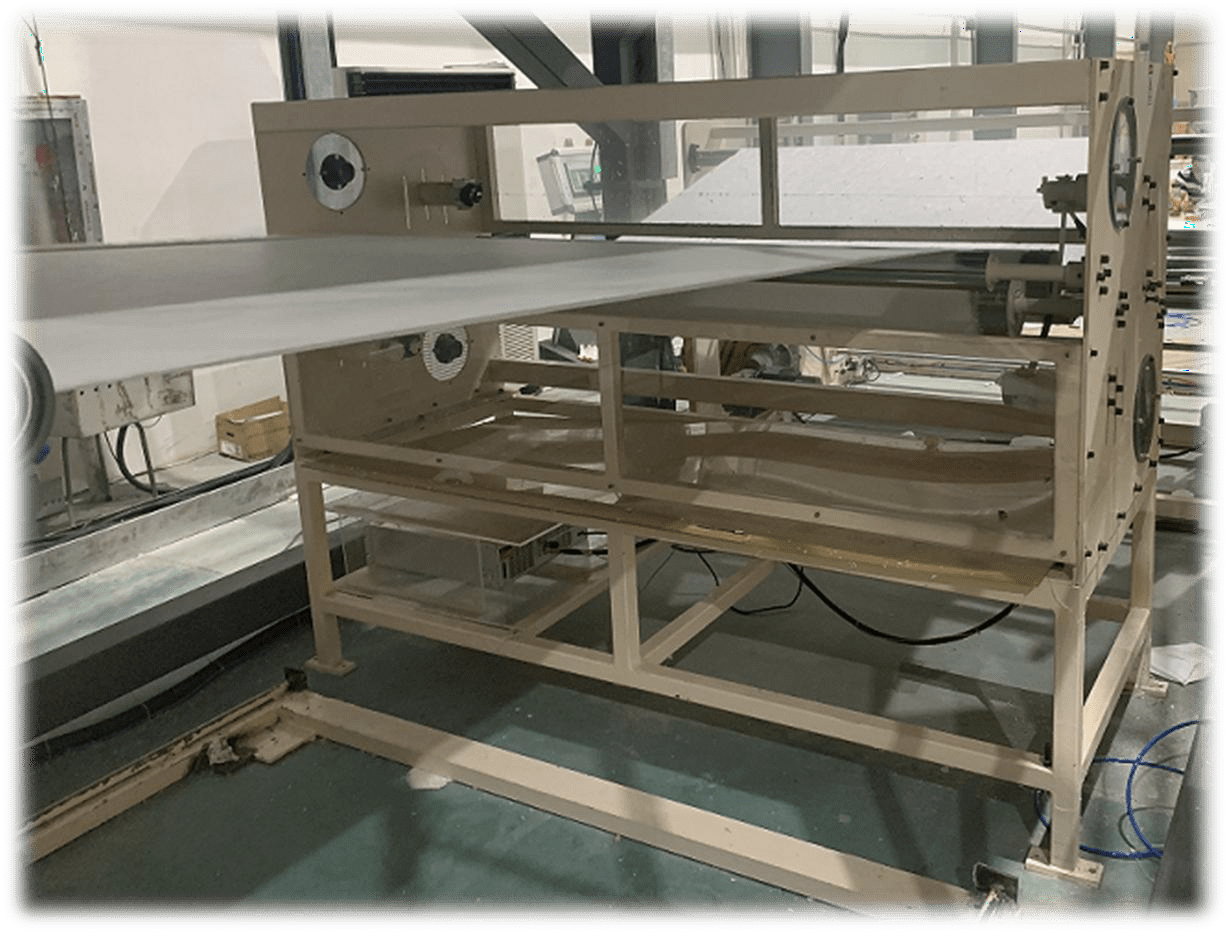

- Winding Machine

- High-voltage Electrostatic Electrets Device

MELT BLOWN PRODUCTION LINE YL 1600 Barus

| No | Item | Technical parameter |

| 1 | Model | YL1600 Barus |

| 2 | Product specification | Final product width: 1600mm, density: 10~30g/m2 |

| 3 | The fiber diameter of the melt-blown | 1.5~5μm |

| 4 | BFE | 95-99% (subject to raw material and other factors) |

| 5 | Output | 1.2-1.5 ton per day |

GENERAL INFORMATION FOR YL1600

MAIN PARAMETERS

|

No. |

Item |

Technical parameter |

|

1 |

Raw material |

MFI=1500 PP |

|

2 |

Melt temperature |

140℃-300℃ |

|

3 |

Max. Die pressure |

20Bar |

|

4 |

Max.output |

70kg/h |

|

5 |

Total installation power |

750KW |

|

6 |

Air compressor |

4KW (Customer prepare) |

|

7 |

Water consumption |

12 m3/hr |

|

MATERIAL LIST |

|

No. |

Name |

Specification |

QTY |

Unit |

|

1 |

Vacuum loader |

300kg/h |

1 |

Set |

|

2 |

Hopper dryer |

100kg/h |

1 |

Set |

|

3 |

90mm Singe screw extruder |

SJ90×30 |

1 |

Set |

|

4 |

Screen changer |

φ120 |

1 |

Set |

|

5 |

Melt gear pump |

100CC |

1 |

Set |

|

6 |

platform |

1600 |

1 |

Set |

|

7 |

Die |

1600 |

1 |

Set |

|

8 |

Spinneret |

1600 |

1 |

Set |

|

MATERIAL LIST |

|

9 |

Roots blower(110kw) |

- |

1 |

Set |

|

10 |

Hot air heater(240kw) |

- |

1 |

Set |

|

11 |

Hot air conveying and insulation system |

- |

1 |

Set |

|

12 |

Collection Device (Conveyor) |

1600 |

1 |

Set |

|

13 |

Air Suction fan(55kw) |

- |

1 |

Set |

|

14 |

High-voltage Electrostatic Electret Device(100kv) |

1600 |

1 |

Set |

|

15 |

Cutting and winding system |

1600 |

1 |

Set |

|

16 |

PLC control system |

1600 |

1 |

Set |

|

17 |

Color mixer |

150KG |

1 |

Set |

|

18 |

Burning oven and ultrasonic device |

|

1 |

Set |

|

MELT BLOWN PRODUCTION LINE YL 800 Barus |

|

GENERAL INFORMATION FOR YL800 Barus

MAIN PARAMETERS

|

No. |

Item |

Technical parameter |

|

1 |

Raw material |

MFI=1500 PP |

|

2 |

Melt temperature |

140℃-300℃ |

|

3 |

Max. Die pressure |

20Bar |

|

4 |

Max.output |

20.8kg/h |

|

5 |

Total installation power |

210KW |

|

6 |

Air compressor |

2KW (Customer prepare) |

|

7 |

Water consumption |

6 m3/hr |

|

MATERIAL LIST |

|

No. |

Name |

Specification |

QTY |

Unit |

|

1 |

Vacuum loader |

300kg/h |

1 |

Set |

|

2 |

Hopper dryer |

100kg/h |

1 |

Set |

|

3 |

YL-65/30 single screw extruder |

SJ65×30 |

1 |

Set |

|

4 |

Manual Screen filter |

- |

1 |

Set |

|

5 |

Melt gear pump |

- |

1 |

Set |

|

6 |

YL-800 Melt blowing die head |

800 |

1 |

Set |

|

7 |

Die |

800 |

1 |

Set |

|

8 |

Spinneret |

800 |

1 |

Set |

|

MATERIAL LIST |

|

9 |

Roots blower |

37KW |

1 |

Set |

|

10 |

Hot air heater |

90KW |

1 |

Set |

|

11 |

Air exhaust blower |

11KW |

1 |

Set |

|

12 |

Collection Device (Conveyor) |

800 |

1 |

Set |

|

13 |

Air Suction fan |

- |

1 |

Set |

|

14 |

High-voltage Electrostatic Electret Device(100kv) |

800 |

1 |

Set |

|

15 |

Cutting and winding system |

800 |

1 |

Set |

|

16 |

Slitting and winding unit |

800 |

1 |

Set |

|

17 |

Electric control cabinet |

800 |

1 |

Set |

|

|

|

|

|

|

|

MELT BLOWN PRODUCTION LINE YL 1600 Barus |

|

MAIN PARAMETERS

|

No. |

Item |

Technical parameter |

|

1 |

Raw material |

PRICE: 450.000 - 480.000 EUR

PRICE: 450.000 - 480.000 EUR