Application

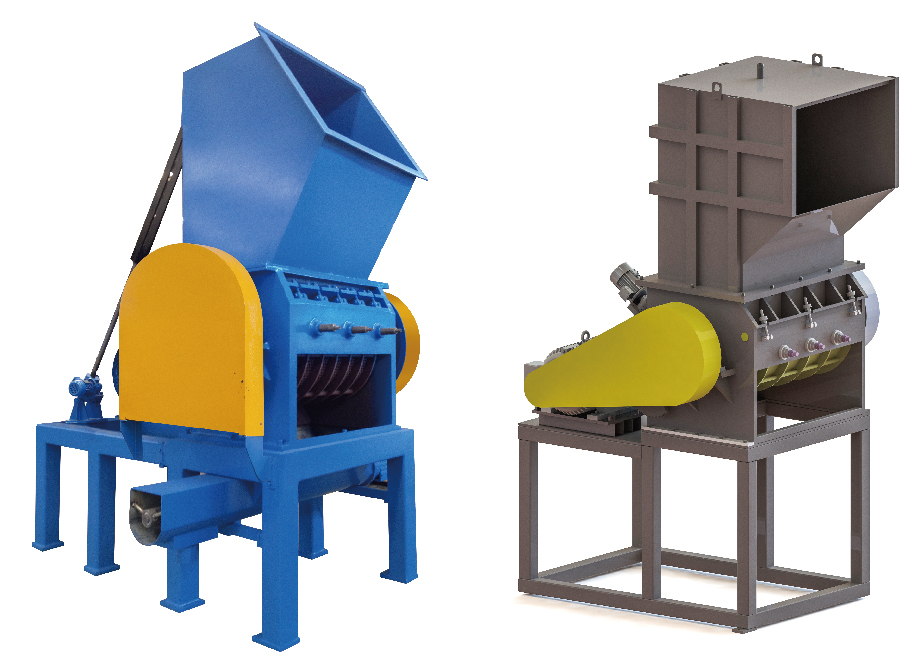

We are professional in design and manufacturing kinds of plastic Crusher Granulators.

Depend on different raw material, the design will be different. We have design for plastic bottles, Plastic pipes, drums, and plastic films. For plastic washing, we also have special design for wet Crusher/Granulator. The screen hole sizes are designed according to final product sizes.

Working Principle

The cutting knives are mounted on the rotor, while the rotor is installed in cutting chamber where the fixed blades are also mounted. After feeding the raw material to the cutting chamber, the rotating knives will rotate at high speed, and the material will go through the gap of the rotating knives and stationary knives. So the material will be cut to small pieces. The final size of product is controlled by screen hole size.

We supply below types of granulators,

1. Granulator for PVC material. This kind of granulator uses smaller pieces of knives, and mostly we use it for PVC pipes and profiles. After granulator, the material will be fed to pulverizer to make powder.

2. Granulator for PE or PP material. The material like pipes or sheets will be put in shredder first, after that, material reduced size will be fed to granulator to get smaller size for pelletizing line. The final product will be granules.

3. Wet granulator. The hopper will be installed hoses to spray the water in the cutting chamber. By this way, it will wash the material while improving the capacity of the cutting. This kind o the granulators are specially designed to prevent machine from rust.

Technical Specification

| Model | YL-600 | YL-800 | YL-1000 |

YL-1200 |

| Motor power (KW) | 22 | 37 | 45/55 | 75/90 |

| Rotary blades (pc) | 8 | 8 | 10 | 10 |

| Fixed blades (pc) | 2 | 2 | 4 | 4 |

| Blade material | SKD-11 | SKD-11 | SKD-11 | SKD-11 |

PRICE: 10.000 - 12.000 EUR